Design for Manufacturability – High-Tech Industry

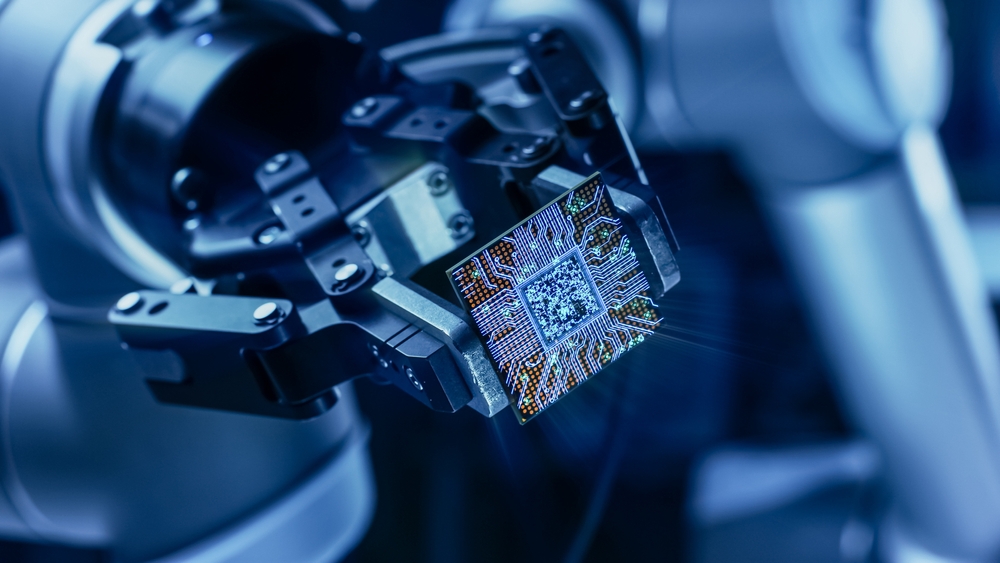

Rise in disposable incomes, emerging middle-class, evolving lifestyle preferences, and the penetration of smart devices has contributed to the overall growth of the high-tech electronics manufacturing industry. Some of the design for manufacturability challenges high-tech electronics manufacturing companies face include:

Shrinking Product Life Cycles & Changing Consumer Preferences

- Shorter product lifecycles as products are becoming obsolete faster, to be replaced by the next big thing

- Consumers seeking greater performance, better features, and flexibility at the lowest price point possible

- Changing focus from Products to solutions to Contextual offerings to enable personalized experiences for consumers

Increasingly Complex Supply Chain Structure

- The high-tech value chain has become very complex with many high tech companies relying on external partners to help design for manufacturability and manufacture their products

- Face consistent pressure to manage Global Supply Chain Quality and Collaboration

- Need to have enhanced visibility across end-to-end supply chains to make smarter business decisions

Reducing Product Prices & Shrinking Operating Margins

- Global competition and new innovations are driving electronic equipment prices down

- Hi-Tech Manufacturers, suppliers face uncertainty with respect to product margins given intense competition

How DFMPro Can Help

DFMPro- a DFM software solution for high tech industry enables engineering executives to make informed design decisions and identify and address downstream manufacturability, assembly, quality and serviceability (DFx) related issues during early design stage. With DFMPro, high-tech electronics manufacturers can focus on getting to market quickly with high quality, innovative products delivered at a competitive cost

Develop High Quality Innovative Products Faster

- Designing first time right, avoid downstream manufacturability issues and rework

- Avoid costly product recalls with high quality products

- Improve Time-to-Market

Be efficient in R&D and Product Development Bringing in Innovation

- Remove inefficiencies and reduce costs from all stages of the product lifecycle cycle to improve profitability and shrinking operating margins

- Knowledge capture & standardization at organizational level resulting in continuous process improvement and reuse

- Scalable framework for capturing and disseminating manufacturing knowledge upstream

Improve collaboration with global suppliers and Operational Efficiency

- Capture supplier capabilities and Improve design collaboration between departments, suppliers and vendors

- Efficient communication with suppliers and vendors help in improving time-to-market

- Sharing real-time usage data with Manufacturing partners or suppliers to unlock innovation

Our Customers

Resources

High-Tech Industry Leader Reduces Part Costs & Improves Order Fulfillment Time

DFMPro provide the ability to reduce manufacturing costs and rework in design to manufacturing process, taking their order fulfillment rate to new levels of efficiency

Tolerance stackup analysis simplified

With Geometric Stackup you can experience just how easy it is to perform 1-D tolerance stackup analysis on complex parts and assemblies and achieve maximum part interchangeability and improved manufacturability of designs- all without having the know-how of dimensional engineering and complex formulas.

Connected PLM enables better and faster product lifecycle decisions

Joe Barkai, a renowned industry analyst, will discuss how a connected product development process utilizes data from connected devices and the connected enterprise. He’ll explore the role of PLM software and design tools like DFX in curating rich context to enhance analytics and improve decision-making.

Why and How of DFM Review Automation

A DFM review automation tool helps in identifying areas in a design that are difficult, expensive or impossible to manufacture. It eases and reduces errors in the design validation process. Learn more in this whitepaper.