Automotive Manufacturing Industry Challenges

The global automotive market is going through its greatest change ever. Automakers are considering different means of autonomous driving and electric-powered vehicles, forcing them to alter their business models and product portfolios. Heavy spending on new mobility and stagnation in key markets is putting automotive market into profit desert. Some of the key automotive manufacturing industry challenges in the journey to profitability include:

Rising Product Complexity and Regulatory Requirements

- Mobility, Autonomous driving, Digitization and Electrification will continue to change the automotive manufacturing industry, causing disruption in the eco-system

- Complying with regulatory requirements will lead to an increase in engineering / R&D costs and require higher volumes to amortize increasing costs

Declining Margins and Skill Shortage

- OEMs have kicked off additional cost reduction efforts, impacting supplier margins

- High investments required for trends like autonomous driving and electric mobility

- Required employee skill set is changing dramatically as the automotive manufacturing industry is moving towards digital transformation

Connected Supply Chain And Changing Role of Suppliers

- Digitizing the connected supply chain drives costs down, engages the consumers more effectively, and collects and uses data for their better service

- Suppliers need to ride the next wave of efficiency gains to overcome the challenges and meet their goals

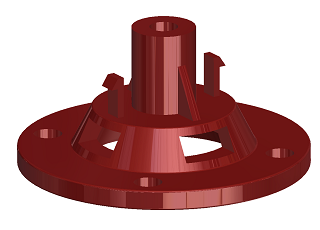

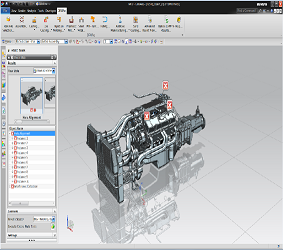

DFMPro – a DFM for the Automotive Manufacturing Industry

DFMPro customization enables engineering executives to make informed design decisions and identify and address downstream manufacturability, assembly, quality and serviceability (DFx) related issues during early design stage. DFMPro helps to capture and disseminate the automotive manufacturing industry best-practices and knowledge in form of DFx guidelines and brings in standardization across the organization

Improve Time to Market and Cost by Reducing Engineering Change Orders (ECOs)

Reducing Engineering Changes (EC) is a Key Enabler for Improving Time to Market and Cost

- Studies conducted by SASIG shows that engineering change can cost anywhere from $5,000 to $7,500 per change

- DFMPro design for manufacturing solution enables EC reduction by addressing issues early during the design stage, thus reducing rework and improving Time-to-Market

Knowledge Capture and Reuse, Bring in Standardization

- DFMPro helps to capture and disseminate the automotive manufacturing industry best-practices and knowledge in form of DFx guidelines and brings in standardization across the organization

- Training new employees

Reduce Cost

- Identifying optimum design alternatives at early stage helps to reduce cost of the product

- Helps in removing inefficiencies and costs from all stages of the product lifecycle cycle to improve profitability and shrinking operating margins

Our Customers

Resources

Automotive Plastics: Automate your way to efficient and high-quality Plastic part design with HCL’s powerful DFX solution

Learn how you can benefit from an automated DFX solution integrated into the CAD systems for best quality Injection Molded Plastic part design, challenges in automotive plastic part design, case study on how a small missed radius led to downtime of the manufacturing line for an automotive supplier and endless possibilities with DFX platform.

Learn More

How HCL’s DFX Platform is Bringing in a Seismic Change to Efficient Design and Manufacturing

This webinar will enable you to deliver quality designs faster for manufacturing, implement Design to Cost mindset at design stage with new DTC module in DFMPro, implement a cultural change to look at Design, Manufacturing and Cost as one single challenge, deploy excellent trace-ability into a model’s health with powerful analytics solution, support seamless collaboration throughout the product lifecycle and Learn how to capture and disseminate the industry best-practices and knowledge and brings in standardization across the organization.

Learn More

How design errors show up as tooling, processing, materials and abuse issues

For a plastic part or assembly to perform as expected, proper consideration must be given to material selection, part design, tooling, and processing using a holistic approach. In a lot of instances, desi-gn errors are mistaken as tooling, processing and material issues. Design errors are even sometimes misclassified as customer abuse.

Learn More