DFMPro- DFM Software for NX

An Engineering Change Order, (ECO) can cost an organization an average of $6,000 per ECO. Experience DFMPro for NX, an easy to use integrated solution that can identify potential downstream manufacturing issues when product costs have increased exponentially.

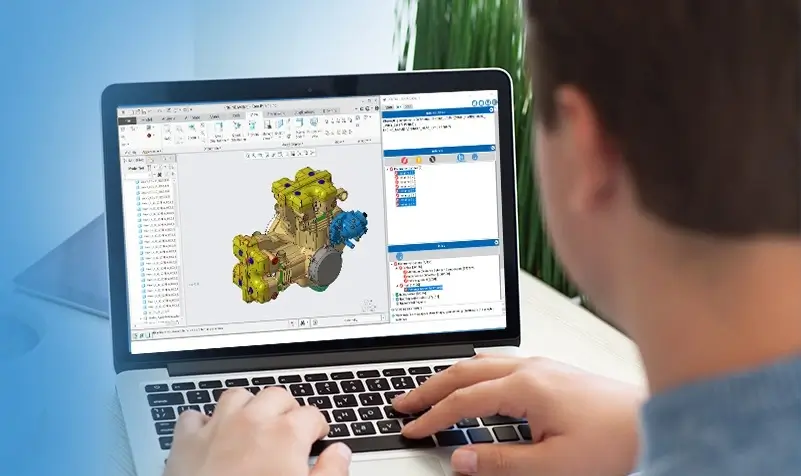

DFMPro for NX™, a best practice driven design for manufacturing software integrated within NX™, help design engineers to identify and evaluate their designs for downstream manufacturability, assembly, quality, serviceability, (DFx) related issues upfront and reduce unnecessary rework and engineering changes. It uses the existing, familiar and proven NX Check-Mate framework, and provides an HD3D interface for problem navigation and tagging. It facilitates out-of-the-box validation for manufacturing process like plastic injection molding, sheet metal fabrication, machining, casting, assembly and more

DFMPro For NX Overview

Fully-Integrated DFM Software directly inside of Siemens NX Interface

DFMPro for NX allows you to

- Pre-empt and address costly design mistakes causing downstream issues in manufacturing and assembly early in the design process

- Automate and formalize the design review process for manufacturability using best-practice knowledge and guidelines provided by DFMPro

- Perform manufacturability analysis for common manufacturing processes like plastic injection molding, sheet metal fabrication, machining (turning, milling & drilling), casting and assembly operations within NX interface

DFMPro Benefits

- Leads to overall cost reduction

- Captures mistakes early in the design stage

- Ensures past mistakes are not repeated, especially by new design engineers

- Leverages experience of experts

- Decreases overall cycle time

- Facilitates on-the-job training of design engineers

SOME OF OUR CUSTOMERS

From large to mid enterprises, across a wide range of industry verticals

Resources Library

Designing for Manufacturability: How Alcon saves time and reduces cost with Creo and DFMPro

Learn from Alcon a pioneering medical manufacturer of eye care components on how they have achieved early visibility into the manufacturability and could save time to market and reduce the product cost with DFMPro and Creo.

An Aerospace Major Reduces Component Costs by 10% with a Critical Look at the Design Complexity

An aerospace major locked in significant savings through systematically reducing manufacturing complexity and cost of component by an estimated 10%.

HCL DFMPro Leads to Digital Transformation

Learn from Honeywell Aerospace on how a proactive approach to Design for Manufacturing will help reduce manufacturing cost and improve time to market.

Why and How of DFM Review Automation

A DFM review automation tool helps in identifying areas in a design that are difficult, expensive or impossible to manufacture. It eases and reduces errors in the design validation process. Learn more in this whitepaper.