Aerospace & Defense Manufacturing

In an era of constant change and transformation, Aerospace and Defense Manufacturing organizations are more focused than ever on incremental innovation and cost reduction as a way to gain competitive edge and drive profitable growth. Faster and Smarter Innovation is now the mantra Aerospace and defense manufacturing for organizations who best respond to these challenges through more efficient R&D investment, better design and manufacturing collaboration and increasing visibility into the complex value chain of suppliers.

Focus on Digital and Advanced Technologies

- Aerospace and Defense Manufacturing companies continue to focus on disruptive technologies such as AI, bigdata, AR, 3D printing, universal connectivity, etc.

- Continued digital transformation but with a focus on low-risk innovation with trusted partners

Accelerated Drive for Efficient

Innovation

- Introduction of several new and more capable models stimulates demand and replacement purchase decisions.

- 50% of the models that will be delivered during the next two years are aircraft that were certified within just the last 12 months

Globalization of supply chain & Multi-tiered structure

- OEMs are pushing local KEY suppliers to expand globally and prefer their Tier 1s to create those relationships.

- Lack of supply chain visibility to OEMs can result in product delays.

How DFMPro Can Help

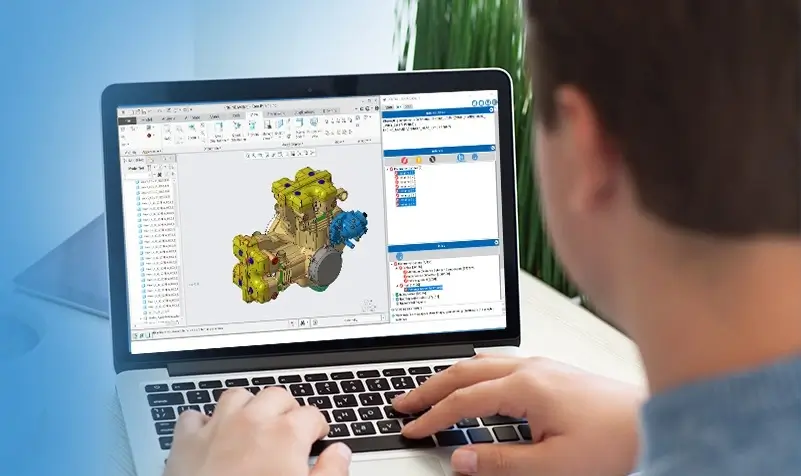

DFMPro enables engineering executives to make informed design decisions and identify and address downstream manufacturability, assembly, quality and serviceability (DFx) related issues during early design stage. DFMPro helps to capture and disseminate the industry best-practices and knowledge in form of DFx design for manufacturing guidelines and brings in standardization across the organization

Improve Product Innovation and Operational Efficiency

- Develop High Quality Systems Designs – 70% of cost of product is determined at design stage and optimized designs have better impact on reducing costs

- Helps in removing inefficiencies and costs from all stages of the product lifecycle cycle to improve profitability and shrinking operating margins

Knowledge Capture and Reuse, Bring in Standardization

- DFMPro helps to capture and disseminate the industry best-practices and knowledge in form of DFx guidelines and brings in standardization across the Aerospace and Defense Manufacturing organization

Reduce Cost

- Identifying optimum design alternatives at early stage helps to reduce cost of the product

- Avoid late engineering changes(ECs) and rework.

Our Customers

Resources

Designing for Manufacturability: How Alcon saves time and reduces cost with Creo and DFMPro

Learn from Alcon a pioneering medical manufacturer of eye care components on how they have achieved early visibility into the manufacturability and could save time to market and reduce the product cost with DFMPro and Creo.

An Aerospace Major Reduces Component Costs by 10% with a Critical Look at the Design Complexity

An aerospace major locked in significant savings through systematically reducing manufacturing complexity and cost of component by an estimated 10%.

HCL DFMPro Leads to Digital Transformation

Learn from Honeywell Aerospace on how a proactive approach to Design for Manufacturing will help reduce manufacturing cost and improve time to market.

Why and How of DFM Review Automation

A DFM review automation tool helps in identifying areas in a design that are difficult, expensive or impossible to manufacture. It eases and reduces errors in the design validation process. Learn more in this whitepaper.