Three product cost reduction tips for design engineers

“We have to launch a new variant in next 1 year and sales team has set us a target of 10% less cost than competition and ensure that there is performance improvement” this is a pretty common statement we hear in NPD briefing meetings. Because of either competitive nature of the business or as customer pressure, it is not new that that product cost reduction is one of the most discussed initiative in the organization. Traditional way cost reduction used to mostly hover around manufacturing cost reduction at plant or at shop level, where more focus of cost reduction is to improve the existing manufacturing process.

With advent of smarter 3D CAD platforms and being able to simulate the downstream processes earlier in design the focus has shifted towards looking at upstream cost reduction. VAVE (Value analysis and value engineering), Process six sigma, QFD, SPC etc various data analysis and methodologies for process improvement have proven extremely useful for driving Lean methodology for manufacturing and operations.

However organizations now realized that since 70% cost is locked in the design phase, whatever quick benefits that can be derived in manufacturing, that has already be done and there is not much impact now as it’s going to impact only 30% of the cost. The major chunk of the cost gets locked at design stage simply because type of manufacturing process driven by functional requirements and geometry of parts is decided with holistic approach. So simply the fate of the part is pretty much decided right when detailed design is created. Hence there is more seriousness towards initiatives like design to cost, early cost estimation or cost or design teams. It has become more like differentiation for innovative organizations to succeed in the market.

Hence, it is crucial for design engineers to keep focus on few simple but vital areas of design which would help in driving the cost reduction.

Material cost is key for high volume additive processes

| Quantity | Material per piece | Process per piece |

10000 | 0.262 | 0.121 |

100000 | 0.262 | 0.082 |

Hence, it is prudent that tooling cost and process can be overlooked for very high volume of production as material contributes most in such scenarios.

However, for subtractive processes it could be different. For Milling, turning operations, where material gets removed mostly, if a part is made from standard billets or bars, and if the material is standard MS or SS, then material cost would be something that need not be worried about. As more important would be to look at process cost. However material cost of Titanium or such precious material could be Hugh even for per mm of material added to a part.

Material | Material rate ($/kg) |

Steel, high strength 4340 | 0.252 |

MS 1020 | 0.521 |

Brass | 2.201 |

SS 304 | 2.775 |

Titanium alloy | 16.254 |

Tungsten carbide | 50.147 |

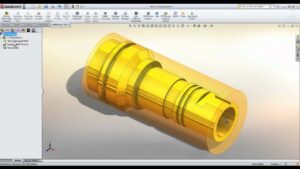

Avoid over processing of mill and turn parts

Buy to fly ratio often used term in aerospace industry is one of the greatest indicators of over processing. It simply takes into consideration of raw material used before manufacturing and how much is left after manufacturing. This is important as every chip of the metal that get is removed in machining needs dollars to be spent to achieve the final shape.

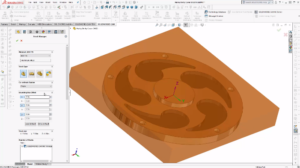

Image 1: Less optimized stock |

Image 2: Right Near net shape example |

For harder material, the material removal rate (MRR) could be even low and that means it is going to take longer milling cycles to crate the final geometry. Near net shape (NNS) hence is the common term used in manufacturing to ensure the shape of material should be circular or rectangular (square) to reduce the cost. This ensures that at time very low material needs to be processed and thus the cost of process goes down.

Also, it is important to note what material is getting processed. For a hole of simple 10 mm diameter and 20 mm depths in SS may take few seconds but for Titanium it may take minutes! There are materials which are difficult to processes. Materials which deform very easily because of heat are equally difficult to process. Aluminum is one of such engineering materials apart from gold, silver, and lead.

Generally, machinability index for materials can help in defining machinability and thus leads to early identification of such materials which are hard to process.

Tight and unnecessary tolerances add to cost!

Tolerance is one of the most neglected areas in design more because design engineers seldom have no idea of downstream manufacturing capability. The challenge with tolerances is that to achieve the tolerances, secondary finishing processes as are required. From design point of view, it is easy to work on one part with tight tolerance while being lenient on tolerance for rest of the parts in assembly. However, it could be manufacturing nightmare to achieve such tight tolerances consistently.

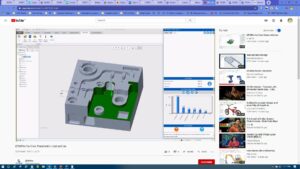

Image 3: DFMPro identified tolerances issues and highlight cost reduction opportunities

The example above depicts a simple hole feature with 12 mm dia. This could be achieved with simple drill in milling process. However, addition of tight tolerance means additional remaining operation and multiple cuts required to achieve the final tolerance. It as well means investments in additional tools and inventory carrying cost. Tolerances should always be driven by the material selection, manufacturing process used and how sensitive your features are to variations.

Last but not the least there are inspection costs that depend on tolerance values used. A dimension that can be measured with simple Vernier or screw gauge is much preferred over 100% CMM inspection.

To summarize, design engineers have great powers to decide fate of the product but also means greater responsibility towards cost reduction. Given that it is at times impossible or very difficult to reduce cost at later stages, keeping material cost, process cost and tolerance in mind is key to successful cost reduction. In part that needs to be milled and there is sharp internal corner present, no matter what happens it has to go through additional EDM process which is slow and expensive. A quote sent to 3 different suppliers will always have this element in the quote and the supply chain person cannot drive further cost reduction as there is no idea to downstream team about what is the intent of a particular feature or what is the functional requirement. With early cost estimation and DFM review techniques, Design engineers can gain better insights into the constituents of cost and work on ‘strategies’ to design the parts rather than just looking at outcome of should cost estimation.