With a major responsibility of part performance on its shoulders, Design for Assembly aka DFA spells efficiency for industries worldwide. A frequent in electro-mechanical industry, Assembly is no alien to industries like sports, fast fashion and the like. While industrial specifications might call for customization, standard design practices for Assembly parts are (and, should) be adhered to.

Study of the varied material available reveal the following common design practices (or, guidelines) for efficiency-

- LESSER THE BETTER

A thumb rule leading industries swear by-aim for simplified and minimal parts in a design. With less room for erroneous/ defective part, simplified fabrication & automation, less requirement of specialized equipments, lesser inventory needs; a simplified production spells optimization! Moreover, in situations where design needs reconsideration, designer can easily go through a design part by part without the hassle of a complex amalgamated product. In most cases, ‘minimum’ can be obtained by opting for an alternate material considering ‘lesser’ time to fabricate (or, produce).

Selecting viable material

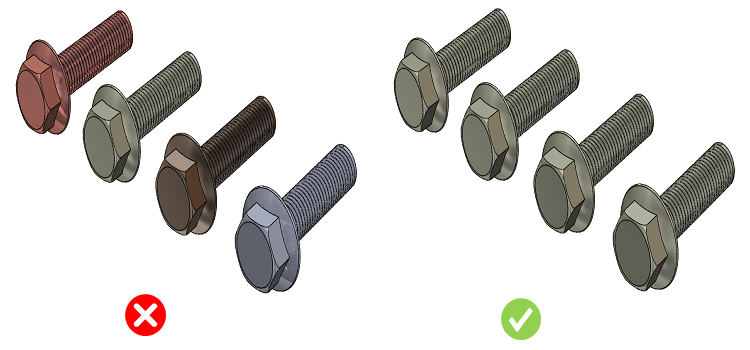

- STANDARDISATION NEVER STOPS TRENDING

An extension of the above point. Using (and, reusing) a select set of parts of materials which can be incorporated into any design results in a nominal requirement of inventory. Further, standardizing end-to-end handling practices and assembly itself, would help one deliver superior quality products at minimal cost. Cataloging available (or, afore designed) part design is always a good idea.

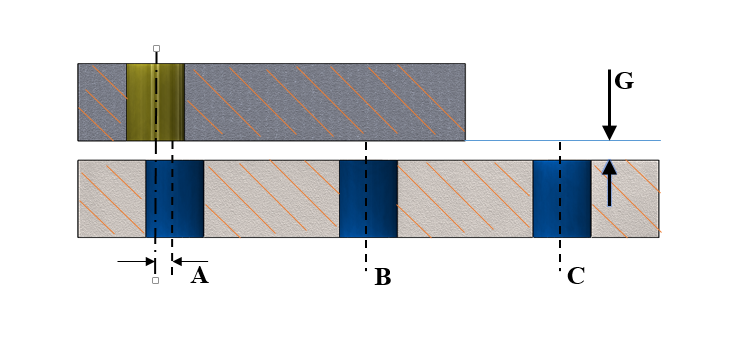

- KNOWING BEFORE DESIGNING

Considering what’s available at hand and then getting down to designing is fundamental. Knowing the potential of available tools and equipment and then designing accordingly will help one reap the benefits of DFM/DFA. Generally, it is recommended to design an Assembly part without too tight a tolerance as it’s usually beyond the scope of most manufacturing capacities. The same must be applied to multi-part connections. Tight tolerances also translate into higher maintenance cost.

Checking Hole Alignment

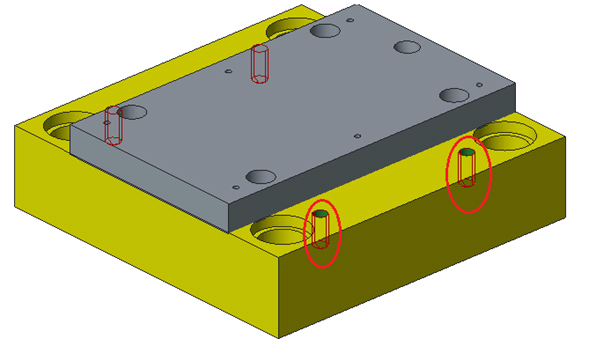

- MULTIFARIOUS GUIDELINES

With the major listed above, an Assembly part can additionally make use of following design guidelines-

- Make scarce use of undercuts and tapers which make use of special tools and require distinct attention.

- Using holes which make use of standard drill machine increases yield and lowers cost. The same must be considered (standard tools at disposal) while designing other features on the part.

- Fancy shapes such as net or fragile features such as flimsy walls, deep pockets, and holes should also be steered clear of – to the extent possible.

Seemingly simple design guidelines often get lost in the course of deadlines, profit, innovation and other eminent aspects of a product. And by the time realization dawns, it’s often a bit late! Knowing this, DFMPro offers a comprehensive list of rules such as Check Contact Materials, Fastener Clearance, Bolt and Screw Rationalization etc. which would analyze a model and present recommendations (and, ensure adherence to Assembly design standards) right at phase one.

A major event of Winter Olympics’ nature does not give a second chance to its participants -it’s win or no win…how about your Assembly design? Is it winning?