Decisions made by engineers during the design stage have cascading implications on product cost, quality and time to market. Given that 30 to 35 percent of engineering effort is spent on rework due to downstream manufacturability and assembly issues, it becomes increasingly important to adopt Design for Excellence methodology as an integral part of the product development process

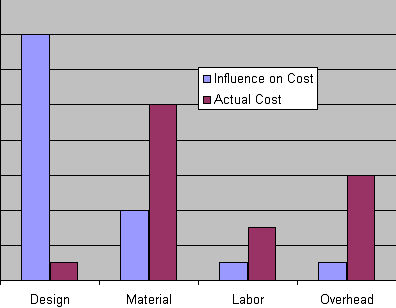

As shown in the Figure 1, actual cost incurred during the design stage is the lowest, but its influence on the product cost is the highest.

Current practices and challenges

Though many organizations have advocated DFx practices, there are several hurdles to a successful implementation. The following discusses some of the methods and challenges in DFx implementation:

DFx checklist and handbooks:

Most organizations incorporate DFx practices in a checklist, which is manually verified by designers before submitting the final design. However, with limited time and resources, manually reviewing designs for hundreds of design guidelines is difficult, time-consuming and error-prone, and there is a risk of missing important design guidelines altogether.

Expert discussion and reviews:

With geographically distributed design and manufacturing/supplier teams, it is difficult for DFx review to happen effectively. Designs that require multiple iterations between supplier and OEM will often lead to delays in production schedule and an increase in overall costs.

Dedicated validation teams:

Organizations have practiced DFx by forming such dedicated teams with the objective of improving designs, part quality and reducing costs.

Success factors for effective DFx implementation

Knowledge capture and reuse:

DFx primarily deals with process knowledge, which is generated continuously in the product development process. It is important that the necessary knowledge and learning produced during the design process is efficiently captured, structured and made available for reuse by design engineers and other product development teams.

DFx automation within CAD:

Effective implementation of DFx is most successful when review of design against an organization’s set of DFx guidelines is seamlessly integrated and automated within the CAD tool such that designers can perform DFx validation immediately and within a familiar environment.

Feedback mechanism:

An automatic verification mechanism is required to ensure feedback from suppliers is captured and incorporated in the design.

Integrated DFx validation software

Geometric DFMPro® is best-practice-driven design for excellence software that enables engineering to make informed design decisions by identifying and addressing downstream manufacturability, assembly, serviceability and quality related issues during the early design stage. It facilitates the implementation of DFx methods and guidelines in a systematic manner and improves the design process. Manufacturing, out-of-the-box industry best practices are available in the form of DFM rules for major manufacturing processes like machining (milling, turning, drilling), plastics/injection molding, sheet metal fabrication, welding, casting and assembly.

DFMPro can help in better understanding of downstream requirements at the right time – that is, when the design is being created. It further promotes collaboration of design with manufacturing, and captures the right understanding of supplier capability to design parts the very first time.

The way forward…

Today, the rules are captured from past incidents and experiences, manually documented, and then programmed into rules. With the acceleration of the Internet of Things (IoT), the near future could have information from downstream captured, processed and heuristic-based rules formed automatically.

This is a synopsis of Bhaskar Sinha’s article published in the Efficient Manufacturing Magazine, Jan 2016 issue. You can read the full article here