During the product design phase, design engineers perform some checks or review design checklist Items that are not directly related to the 3D or 2D CAD data. These checks may be less critical from a design point of view. Still, they may be necessary considering process adherence or manufacturing/functionality aspects that cannot be checked automatically due to lack of the required details in the CAD design and need to be performed manually or just checked off as “done,” e.g., Prototype created before final revision, availability of structural analysis report for the part, tooling feasibility discussion report confirmation, checking fixture/gauge standards, BOM addition, 3D/2D exploded views addition, etc. These DFM manual checks ensure that critical items are not missed and are precisely taken care of. Also, the designer won’t be able to omit anything that may alter the results. Checklists created by individuals or groups of people might be incomplete. Maintaining a checklist can be time-consuming and error-prone if it involves manual updates separate from the system. It also results in incorrect interpretation if it’s not captured/updated correctly.

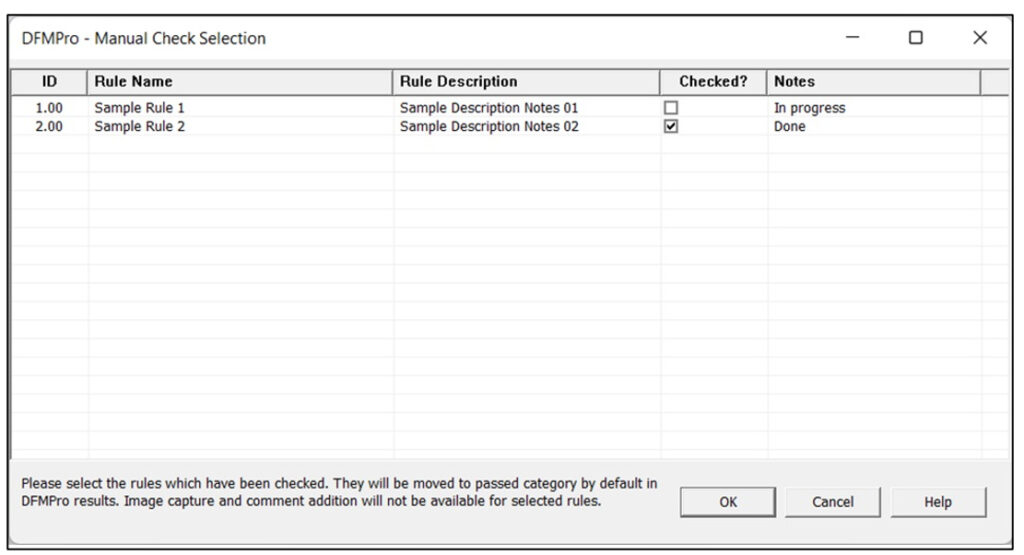

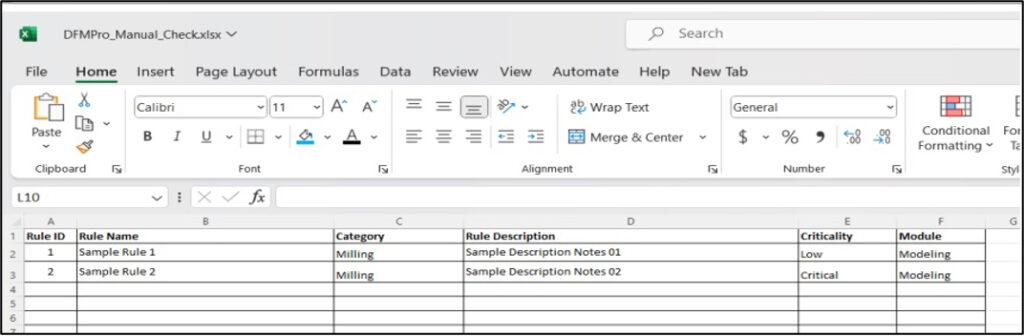

A typical organizational design checklist contains checks that can be automatically verified from CAD data (geometry, metadata, etc). DFMPro automates this checklist. It is essential to have checklist verification results in a single report. DFMPro’s Manual Check selection is a new functionality of DFMPro for clients who face the challenges of manually maintaining and updating design checklists.With the Manual Check functionality integrated within DFMPro, designers can now confirm checklist items during the DFMPro analysis. It helps SMEs capture all items from their existing review checklists in the DFMPro knowledge base. The Manual Check rules are based on the predefined Excel document available within the DFMPro installer. Users can customize the list by adding the set of manual check rules in this document, which will be available in Rule Manager for selection.Design engineers must not follow different systems to validate the required checklist items.

Using DFMPro Manual Checks is straightforward. It allows users to re-confirm if the required checks are performed on the design manually and sign off accordingly. The tool also helps the reviewer verify if the design engineer executes all the standard manual checks. If any checks are not performed, they are flagged in DFMPro results, prompting the user to confirm them prior to submission or add justification for pending items. This ensures that all the checks from the list are are executed and confirmed.

Here are a few Key benefits of DFMPro Manual Checks:

- Automation of the review checklist

- Checklist information is captured in the DFMPro knowledge base for easy maintenance

- Ease of checklist updation

- Confirmation of checklist items by the designer during DFMPro execution

- Manual checks are customizable as per organization guidelines

- Provides detailed reports of passed/recommended checks through reports

- Single workflow and report for manual as well as automated Design for Manufacturability (DFM) checks

To have a detailed demonstration of this functionality and to know more about the DFMPro Manual Check and its capabilities, write to us at dfmpro.marketing@hcl-software.com