Design and Manufacturing are going through a phase of tremendous transformation, due to advent of new manufacturing technologies, widespread manufacturing networks, decentralized design centers and use of new materials. With new products being launched in market daily, apart from time to market, the success of a product heavily depends on two key aspects: Quality and Cost. For this, design engineers need to have advanced enterprise solutions that provide upstream visibility into a products manufacturability health and increased awareness about the impact of early design decisions on the cost of the product. However, apart from designers, other key stakeholders like manufacturing teams can also benefit greatly with solutions that reduce the impact of late engineering changes on cost, quality and time.Till date, an “Over the wall” design process was and is reflective of a typical method of designing and manufacturing of products.

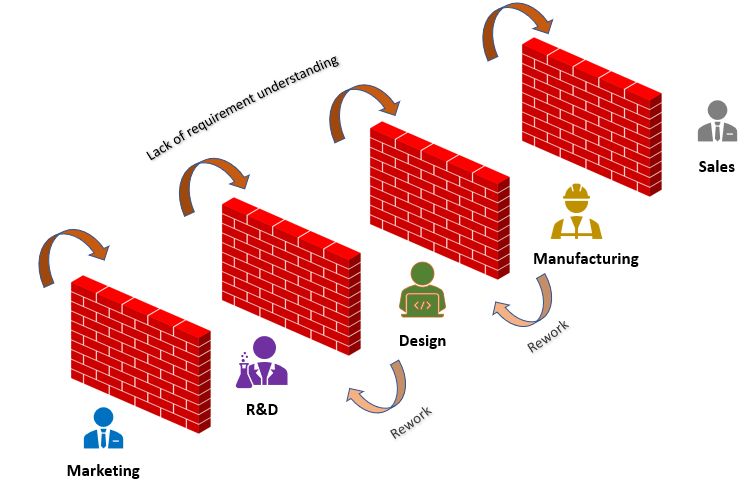

Figure 1: “Over the Wall” design process

In this process, every department works and completes their tasks independently without consulting the other departments about the impacts of their decisions. This process is error prone, cumbersome, and introduces high levels of rework due to loss in communications. In our context, the design team is unaware of the manufacturing team’s requirements and throws designs over the wall expecting the manufacturing teams to figure out ways of producing them. However, this approach leads to products which are either difficult or very expensive to manufacture. This in turn, affects the sales of products because they are expensive to sell in a price sensitive market.

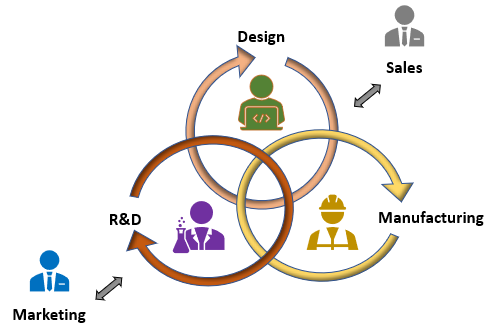

The reason for this approach is that quality was and is, perceived as a headache of manufacturing while effective cost management was done by costing experts. However, with rapidly changing product landscape, this mindset is changing, and organizations are focusing on “concurrent and collaborative engineering” where what is designed gets manufactured with minimal rework and cost impact. This has put the designs teams in the spotlight, where they are expected to cover the estimated 70% of cost of product right during design stage which means, collaborating effectively, understanding critical factors that impact manufacturing and reducing downstream overheads. Organizations are looking to eliminate the communication gap that exists between design and manufacturing with help of powerful solutions to drive standardization across these different silos.

Even the traditional collaboration workflows involving design reviews by manufacturing and cost experts are not scalable due to significant bandwidth issues faced by the SMEs. Hence it is important that design engineers are empowered to take decisions which are automatically reviewed against best practices defined by SMEs. In case of conflicts or additional expert inputs only, the SMEs are involved.

Figure 2: “Collaborative Engineering” design process

Organizations are also realizing the importance of traceability into the health of a design throughout the course of its lifecycle to ensure effective corrective actions are taken. The goal is to track any downstream quality of cost issue right to each revision level of a design. Many organizations are now tasked to look for a solution that addresses these core aspects for implementing a successful DFX strategy, which will enable them to release products at faster pace that ensures they remain relevant in today’s fast paced world.

To aid this transformation, DFMPro has now taken shape of an all-encompassing DFX solution, which supports a holistic approach towards design.

Figure 3: Concurrent and collaborative engineering with DFX

Figure 4: Some of the functionalities enabled through the DFX Platform

The powerful DFX platform enables manufacturing validation closely tied with feature-based cost, that empowers design engineers with the right level of information to take educated decisions early in design cycle. This rough order of magnitude cost (ROM) enables a design direction, that is inclusive of both cost and quality aspects of a successful design. It puts the design phase on the right track right from the get-go, that allows early changes to the design based on feedback received from key stakeholders. Organizations can ensure, that both DFM and cost inputs are vetted and captured in an automated workflow, that give confidence to the design engineers, about not only the design recommendations given by the system, but also understand the impact of these decisions on the eventual cost of the part.

However, generating this huge manufacturability data is of no use, if it cannot be comprehended easily. To aid this, the DFX platform also comes with a powerful Analytics module, that enables excellent tracking of designs across various teams to its logical closure and provides a complete picture of product lifecycle for management consumption. Effective collaboration is a vital component in the value chain to ensure all aspects of design and manufacturing are covered seamlessly. To enable this, DFMPro also allows easy integrations with leading PLM systems to store and share useful data for faster reviews, thus completing the ecosystem.

The combination of these three powerful elements enabled by one single platform (DFM + Cost + Analytics) that works inside a CAD/PLM space, is the ideal solution for smarter global enterprises.