Predictive Analytics in DFM: Anticipating “What Will Happen?”

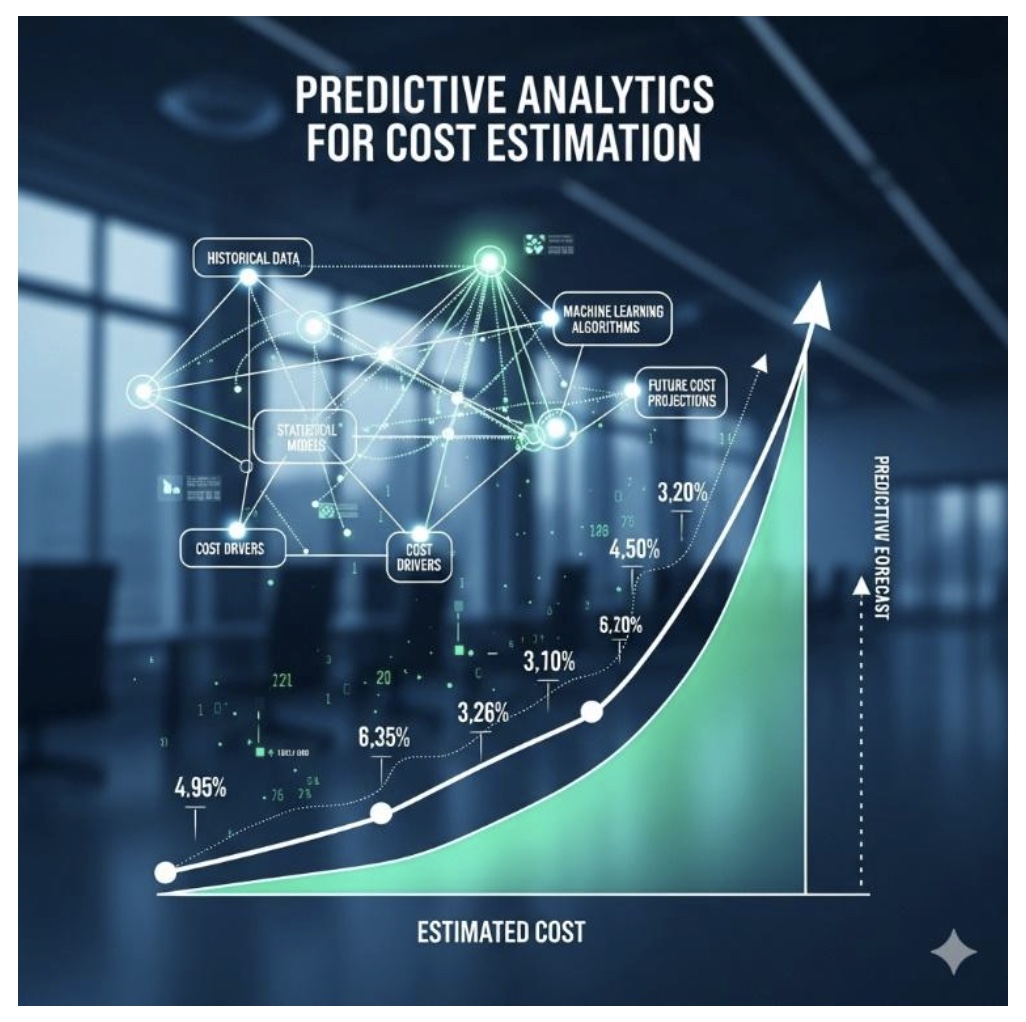

Predictive analytics represents a significant leap forward from understanding the past to forecasting the future. In the context of Design for Manufacturability (DFM), it harnesses historical data, statistical models, and machine learning algorithms to estimate the likelihood of future outcomes, risks, and trends. By answering the question, “What will happen?”, predictive analytics empowers organizations to shift from a reactive stance to a proactive one, allowing users to anticipate potential DFM rule violations, forecast cost implications, and estimate time-to-market delays before they become unavoidable problems. This foresight enables early intervention and optimized resource allocation.

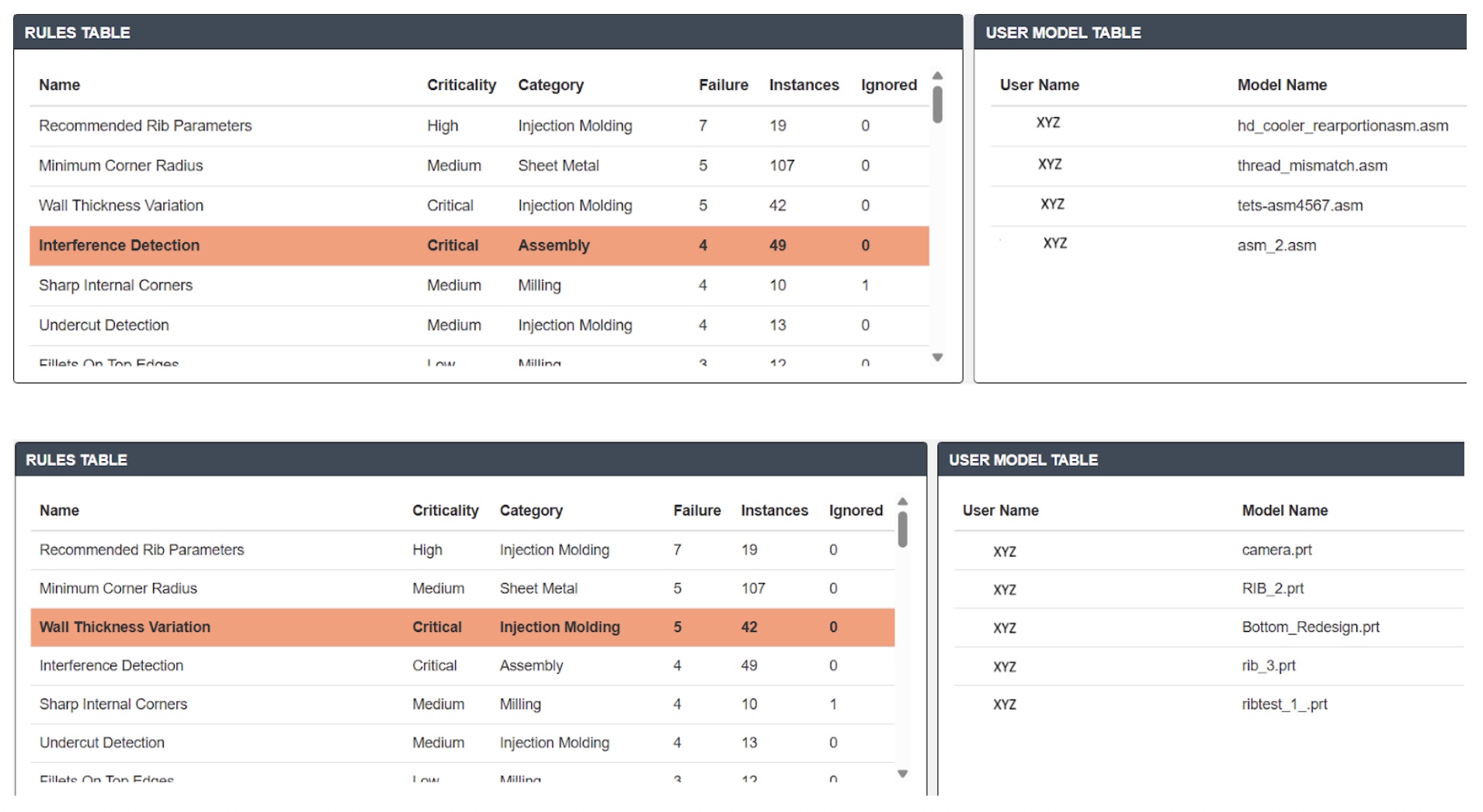

Key Components of Predictive Analytics in DFM

1. Failure Prediction

This represents the most direct application of predictive analytics within DFM. Machine learning models—such as classification algorithms like logistic regression, support vector machines, or neural networks—are trained using historical design data, DFM rule violation logs, material properties, and manufacturing process parameters.

These models can then estimate the likelihood of a new design or specific design feature violating a DFM rule even before a full DFM analysis is conducted or the design is finalized.

- Predicting Undercut Issues: Identifying geometric features likely to cause undercut problems in injection molding, based on complexity and prior designs.

- Forecasting Weldability Problems: Anticipating potential weldability issues in complex assemblies, considering material combinations and joint designs.

- Estimating Wall Thickness Failures: Assessing the probability of a part failing minimum wall thickness requirements, based on its overall size, shape, and intended manufacturing process.

This enables designers to course-correct early, saving significant time and cost associated with late-stage redesigns.

2. Cost Estimation

Predictive analytics extends beyond identifying manufacturability issues; it can also forecast the financial impact. By analyzing historical manufacturing costs linked to specific design features, materials, and DFM compliance levels, predictive models can provide accurate estimates of manufacturing costs for new designs.

- Tooling Costs: Predicting the complexity and cost of molds or jigs based on design features.

- Material Wastage: Forecasting scrap rates based on design geometry and anticipated DFM issues (e.g., porosity in castings).

- Labor Hours: Estimating direct labor required for assembly or specific manufacturing operations, influenced by design complexity.

- Rework Costs: Quantifying the potential cost of addressing predicted DFM issues on the shop floor.

3. Time to Market (TTM) Prediction

Delays due to DFM issues are a major contributor to extended TTM. Predictive analytics can forecast review and iteration timelines by analyzing historical project data, including the number of DFM issues, their severity, and the time taken for resolution.

- Likely number of DFM review cycles a design will undergo.

- Estimated time required to resolve predicted DFM violations.

- Potential delays in tooling procurement or manufacturing ramp-up due to DFM-related changes.

This enables more realistic project planning and scheduling, allowing project managers to build in appropriate buffers or proactively allocate resources to high-risk designs.

4. Risk Assessment

Predictive analytics can develop comprehensive risk scores for designs based on the aggregation of predicted DFM issues, cost implications, and potential time delays. Designs are flagged at high, medium, or low risk for rework, production delays, quality defects, or higher-than-expected costs.

- A design with many predicted wall thickness violations, complex features, and novel materials might receive a “high-risk” score.

- A simpler design with few predicted issues and standard materials would be “low-risk.”

This risk categorization allows organizations to prioritize engineering resources, allocate senior designers to complex, high-risk projects, and streamline the approval process for low-risk designs, accelerating their journey to production.

5. Supplier Capability Prediction

Predictive analytics can also forecast a supplier’s ability to successfully manufacture a design with acceptable quality and cost. This prediction is based on their historical performance, stated capabilities, and the new design’s characteristics. This process aids in strategic supplier selection and mitigates supply chain risks even before RFQs are issued.

Benefits of Predictive Analytics in DFM

- Proactive Issue Resolution: Identify potential problems before they occur, enabling digital modifications that are faster and cheaper than physical rework.

- Informed Resource Allocation: Allocate engineering and tooling resources effectively to prevent bottlenecks and optimize workflows.

- Enhanced Planning and Scheduling: More accurate cost and timeline predictions lead to better budget management and improved delivery reliability.

Challenges of Predictive Analytics in DFM

- Requires Robust Historical Datasets: Accurate models depend on large, clean, and structured historical data.

- Model Accuracy Depends on Data Quality and Training: Models must be regularly retrained to stay relevant and avoid overfitting or underfitting.

- Advanced Analytics Tools and Expertise: High-quality predictive models may require specialized platforms and skilled data scientists.

- Interpretability of Models: Advanced models can act as “black boxes,” making Explainable AI (XAI) essential for trust and adoption.