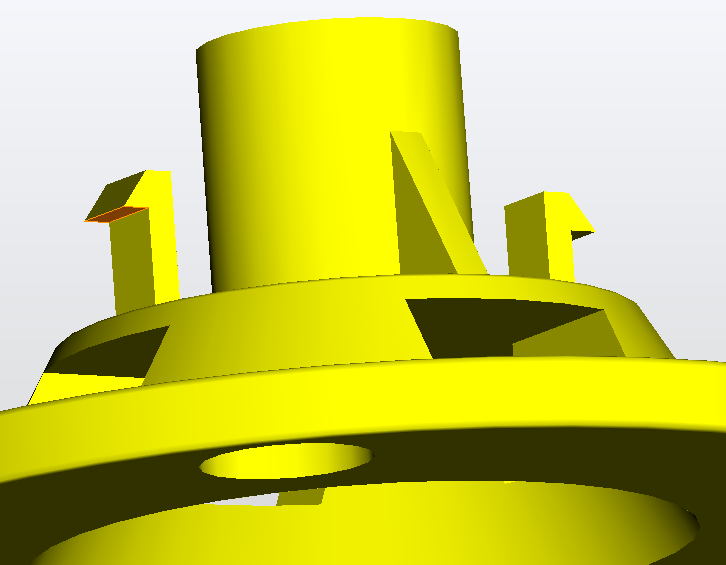

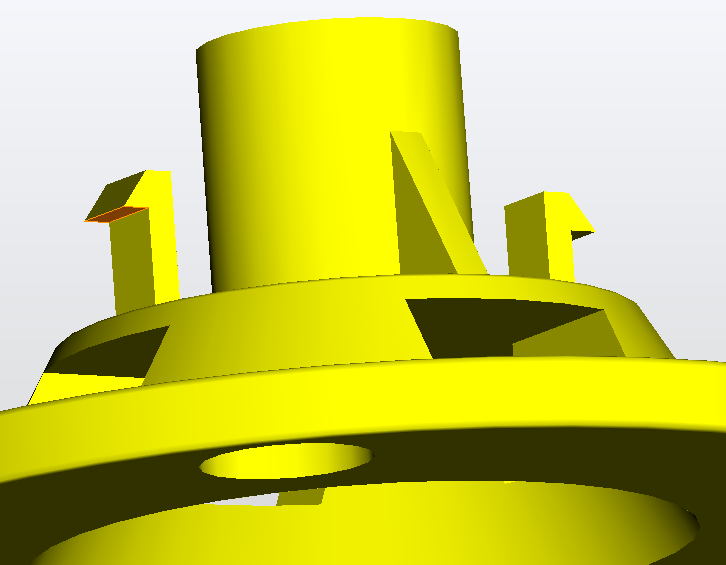

| A major cost component in 3D printing is machine time. Parts with features requiring support structure require more time for the machine to print the part. This increases the cost of printing the part. Features like undercuts, negative drafts, overhang faces require support structure along the filling direction. Hence the part should be designed in such a way that it needs minimum support structure while 3D printing. This also ensures that the time required for finishing the part is also reduced. | |

| |

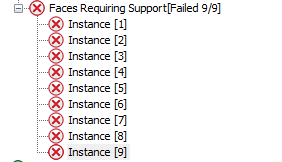

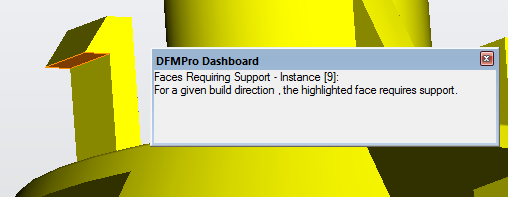

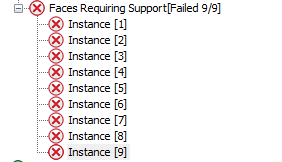

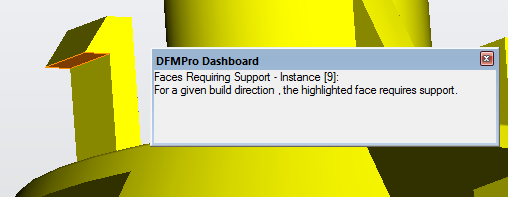

| Imagine how difficult it would be for the designer to manually analyze the geometry of the part to detect such features. When the product complexity increases, it would be almost impossible. To solve this problem, we are shortly introducing a design check within Geometric DFX for checking your parts for 3D printability. The rule automatically detects the best filling direction for the part. The user can change the default plane selected for the filling direction and also flip the direction as required. On analysis, it highlights all the features in the design which require support structure. The designer can then modify the feature suitably or ignore the error if the feature is essential from a functionality point of view. | |

| |

| Let’s see more upcoming rules in Geometric DFX on how you can design your part for 3D Printing. | |