Background

Background

Let us face it. Optimizing product cost is good “for the health” of everyone from the product designer to the CEO and everyone between and below. Corporations can even go out of business if the costs of goods sold (COGS) are not in control. A major portion of the COGS is the individual part cost.

To keep everyone on their toes regarding COGS, most corporations judge project success on three “Ons.” Everyone who is a part of the project is rewarded or penalized based on how they are met.

These are:

- On time

A fully functional product is ready for the market when it was committed to be launched at the start of the project. To meet these time deadlines, products may be launched with many cost optimization opportunities “left on the table.” The logic is “we will come back” to reduce the cost.

Yeah, right! The high costs are built in forever in most situations.

- On budget

- Cost of the product

- Cost of development

This one is obvious. Both the cost of the product and the resources spent on the development need to be controlled.

- On specification – need to meet the product requirements

- Cost to fix if not on spec

The last-minute scramble to make sure the product meets specifications not only needs unplanned resources but also compromises in the cost.

The Role of the Designer and Various Aspects of Costs

A product designer is like the quarterback in American football. The quarterback is responsible for the outcome of each individual play and his successes and failures can have a significant impact on the fortunes of his team. Even the strongest offence and defense team cannot make up for the deficiency of a quarterback.

Likewise, the design engineer plays a major role in the performance of the product including its cost. The others in the team such as the material supplier, the tool maker and the manufacturer cannot make up for the deficiencies in the design or the cost. A clear majority of the apparent material, tooling, processing and abuse issues and costs can also be linked back to design errors.

AsBackground designers, we take pride in creating robust products at the optimum cost. Every design should obviously be robust enough to meet or exceed the functional requirement over the projected life, intended environmental conditions and the physical appearance. However, considering the competition and changing consumer preferences, every designer should also ensure that the product is as cost effective as possible.

Let’s look at what makes up the total cost of a product and what costs can be avoided or eliminated.

Normal Costs

- Development costs (reasonable CAD, analysis, prototyping, verification costs)

- Tool, tool development and qualification costs

- Total part cost – n x the reasonable individual part cost (‘n’ being the total number of products manufactured)

Avoidable Costs

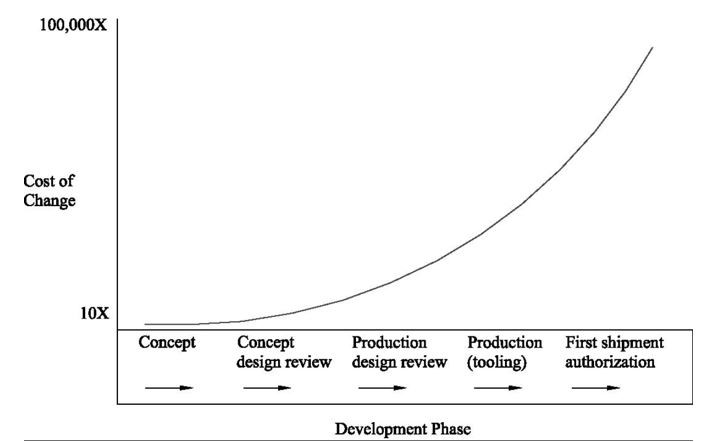

Avoidable costs are those that are attributed to the direct and indirect costs (scrap costs, wasted engineering resources cost, tooling costs, etc.) that occur due to design errors and engineering changes that could have been avoided. Figure 1 depicts the traditional cost of design change curve for the product lifecycle. As one can see, the cost of a design error and change increases exponentially, the later it occurs in the development lifecycle.

Figure 1

Companies pay even a bigger price if errors are detected after the product is delivered to customers. It not only leads to expensive recalls but can completely damage a company’s reputation.

The General Motors recall due to the faulty ignition switch is a recent example of how a simple design error led to huge losses for the company. The cost for getting the switch designed right in the first place would have been 57 cents [1]. The total cost of the recall was $4.1 billion as of Feb 4, 2015 [2].

Opportunity Costs

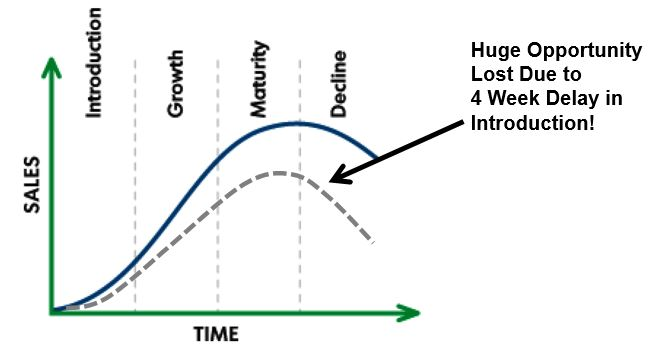

The figure below represents a commonly acceptable life span of a product.

The solid line shows the total anticipated sales for a product over its intended life. The dotted line represents what may happen to sales if the product release is delayed by 4 weeks. The difference between the integrals of the two curves potentially represents the total revenue loss or the total opportunity costs and may run into millions of dollars.

Leading aircraft manufacturer, Boeing had to temporarily halt the deliveries of Boeing 787 because of the battery overheating issues. This cost the aircraft manufacturer approx. $600 million [3] in direct costs. As large as this figure is, it may still dwarf compared to the loss in opportunity costs. Losing the sales of even 5-6 aircrafts to the competition may mean revenue losses of over a billion dollars.

Leading aircraft manufacturer, Boeing had to temporarily halt the deliveries of Boeing 787 because of the battery overheating issues. This cost the aircraft manufacturer approx. $600 million [3] in direct costs. As large as this figure is, it may still dwarf compared to the loss in opportunity costs. Losing the sales of even 5-6 aircrafts to the competition may mean revenue losses of over a billion dollars.

(Please see my article “Eye-opening Impact of Simple Design Errors on Product Costs”, Plastics Engineering, Oct 2016).

Typical Processes to Determine and Optimize Costs

Unfortunately, the cost estimation of a part has no formal procedure in most organizations.

The most common ways are:

- Pure “guesstimate”

- Using some unproven rules of thumb such as part weight multiplied by a certain factor

- Using a previous part as a bench mark

- “Phone a friend”. Going to the cubicle next door and guessing the cost together

- “Ask the Expert”. Going to an inhouse real or perceived expert. If not a real expert, he/she may follow the previous steps to provide an “expert” estimate. If indeed an expert, he/she may not be able to have the insights into the part to provide the optimum cost or make suggestions on optimizing the cost.

- Go to the procurement person. He/she may either guess it himself/herself or follow the previous steps including a calling a few chosen suppliers. Again, even if the cost estimation is close to the real cost the process may not the insights into the part to provide the optimum cost or make suggestions on optimizing the cost.

- (This is one way the engineer can get into real trouble). Depending heavily on a chosen new or existing supplier to help in the determination and optimization of the cost. The supplier in question now expects to get the order for the part because of the time and resources it has spent in the costing and optimization of the part. More serious than that, the supplier may have shared some proprietary techniques in the process. There is trouble when the procurement department finds out that the engineer has basically committed the job to a certain supplier!

- There are many other equally inefficient ways to come to the wrong or an unoptimized cost after spending a good amount of energy.

Holistic Design and How Focus on Cost During Design Will Help

| Consideration to the following is required for a well-designed and cost optimized plastic part or assembly:

This is analogous to the four wheels of a high-performance car. |

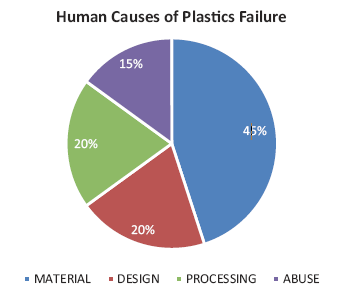

In his book Failure of Plastics and Rubber [5], David Wright conducted an analysis on 5,000 failed parts and came up with the causes for the failures shown in the figure below.

Therefore, a designer may conclude that he or she is responsible for only twenty percent of the failures or cost overruns. What appears as materials, processing, tooling, or misuse issues may in a lot of cases can be traced back to fundamental design issues that may manifest themselves as the former.

Let us look at a few examples:

- Material

A plastic part cracks in use. We assume that it is the material weakness and change it to a different and possibly more expensive material. This not only makes the part more expensive, it also results in more engineering hours, more tooling, part qualification, inventory purge, etc.

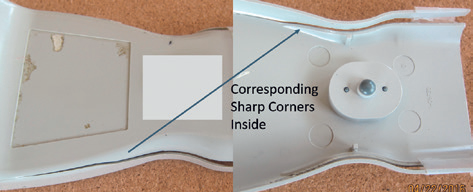

In the example below, the reason for the crack was not the material (Polycarbonate). It was the sharp corner in the corresponding inside walls.

- Design

Poor design, besides resulting in higher material, tooling and processing costs, will result in many avoidable costs and opportunity costs as described above.

- Tooling

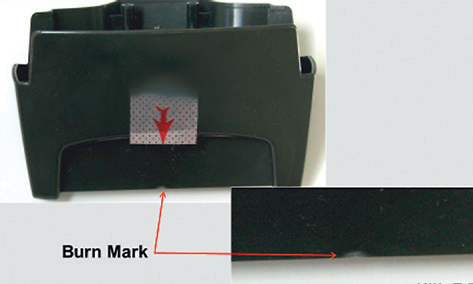

We often blame warpage, scuffing, poor filling, etc. on poor tooling. These may be the result of uneven walls, long thin walls, flow from thin to thick sections, inadequate draft angles, etc. In the picture below, the burn mark is supposedly due to poor venting. The fact is that the long thin rib allows the toolmaker no place to vent – clearly a design issue.

- Processing

Thick sections because of poor design (rib thickness at the bottom, for example) lead to higher cooling time (proportionate to the square of the thickness). In smaller parts, this may add significantly to the overall costs.

Poor yields, not meeting the dimensions, warpage, flow marks, sink marks, etc. are often blamed on poor processing. The truth is that many of the issues are caused by design errors.

The flow marks and lack of filling in the example below (left) are caused by a thin area of plastic surrounded by thick area (hesitation effect). The ugly lines on the right are caused by thick ribs on the other side of the wall. No amount of adjustments can totally get rid of these issues. The result will be a substantially reduced yield resulting in higher costs.

DFMPro – A Design Assistant Solution

Organizations need to have a good sense of the cost early in the design stage and cannot wait until a supplier has been selected. DFMPro provides the tools to estimate and optimize the costs right from the early stages.

Two Sides of the Same Coin!

There are two aspects of design that impact costs, direct and indirect. The former consists of the material and direct manufacturing costs. Indirect costs are often hidden. These consist of costs such as ease of manufacturing, assembly, safety issues, etc. DFMPro provides a rule-based approach to provided information on both aspects.

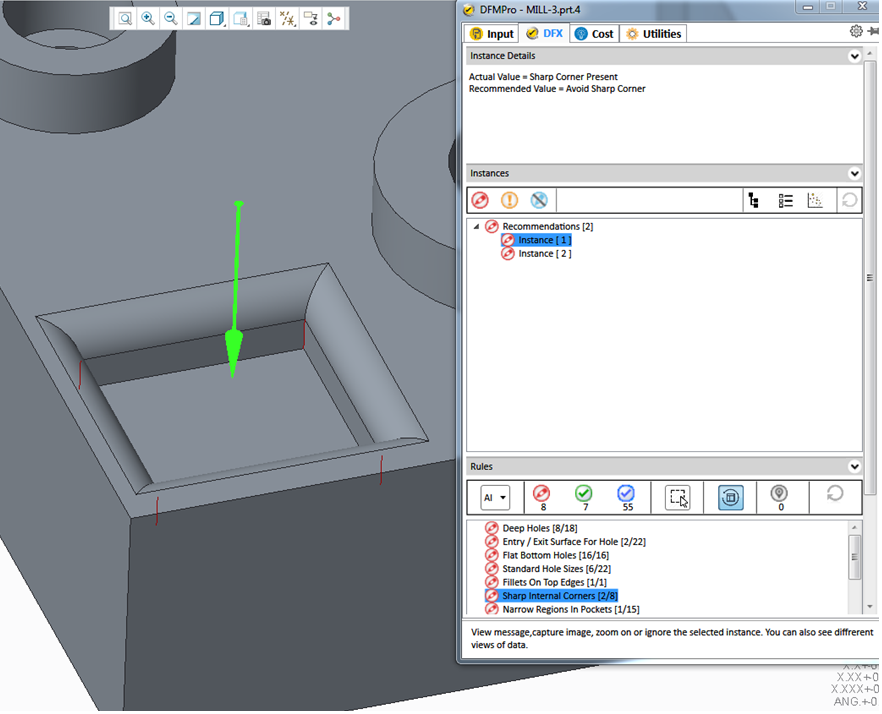

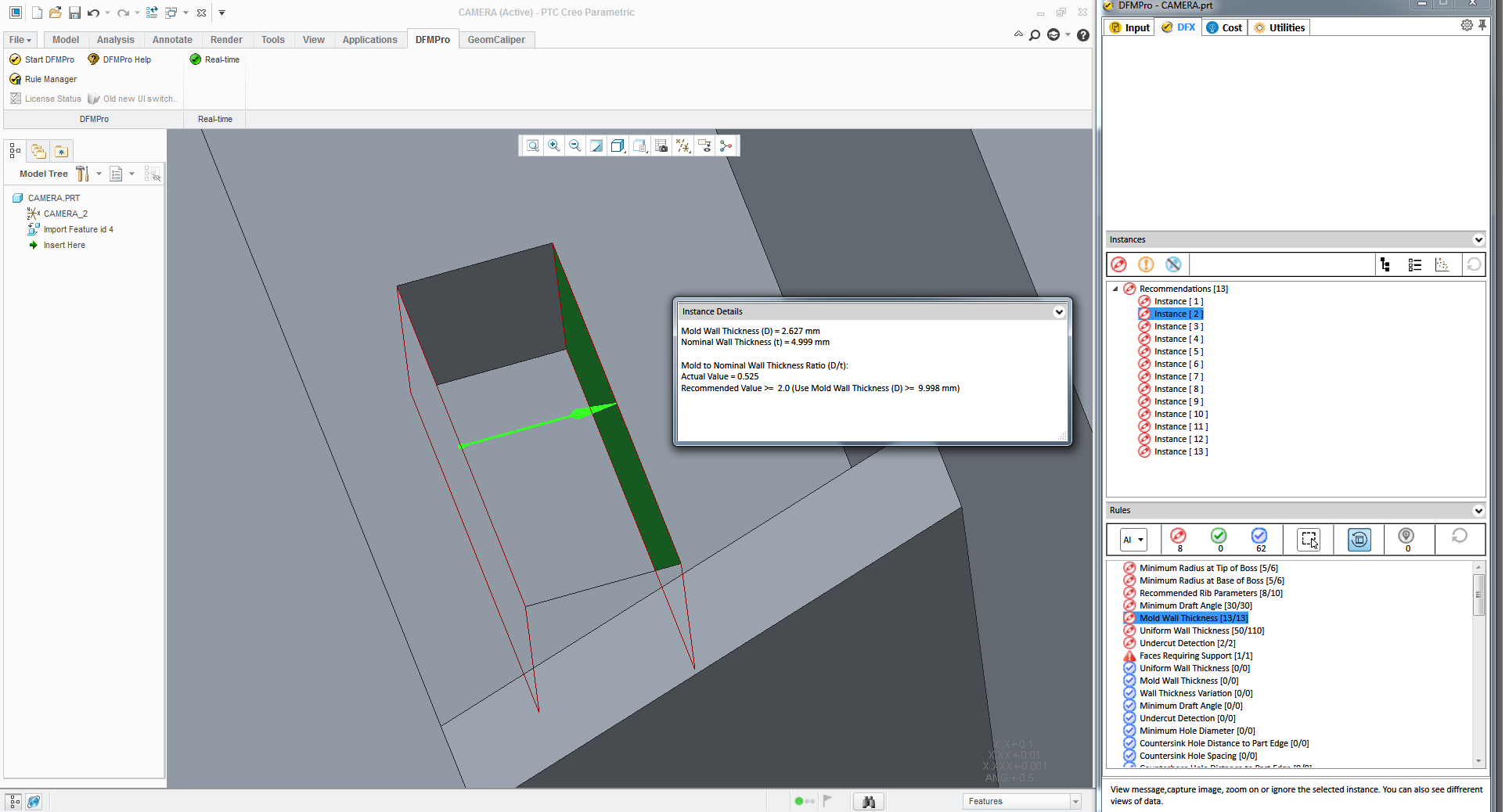

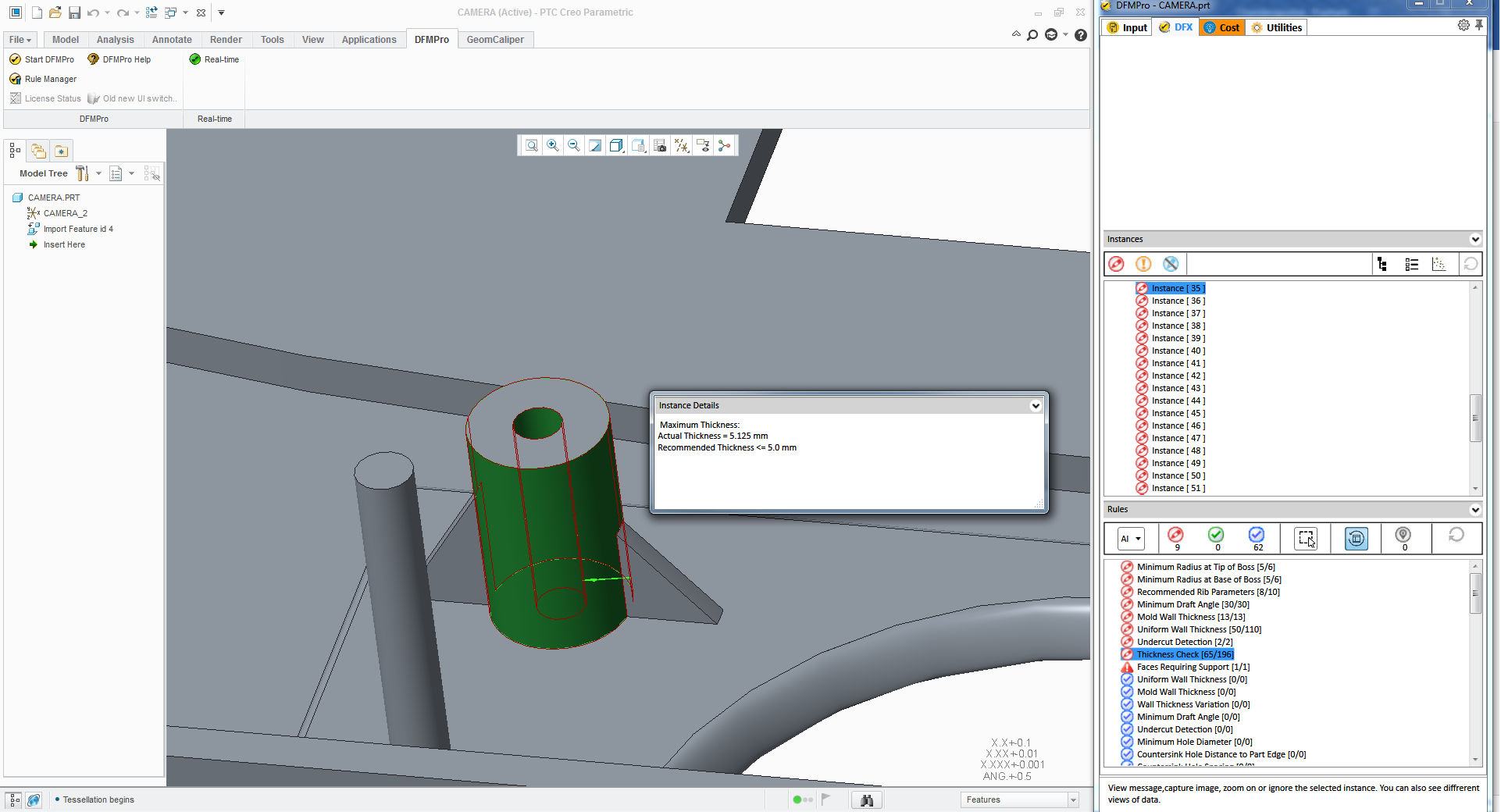

Fig: DFX View

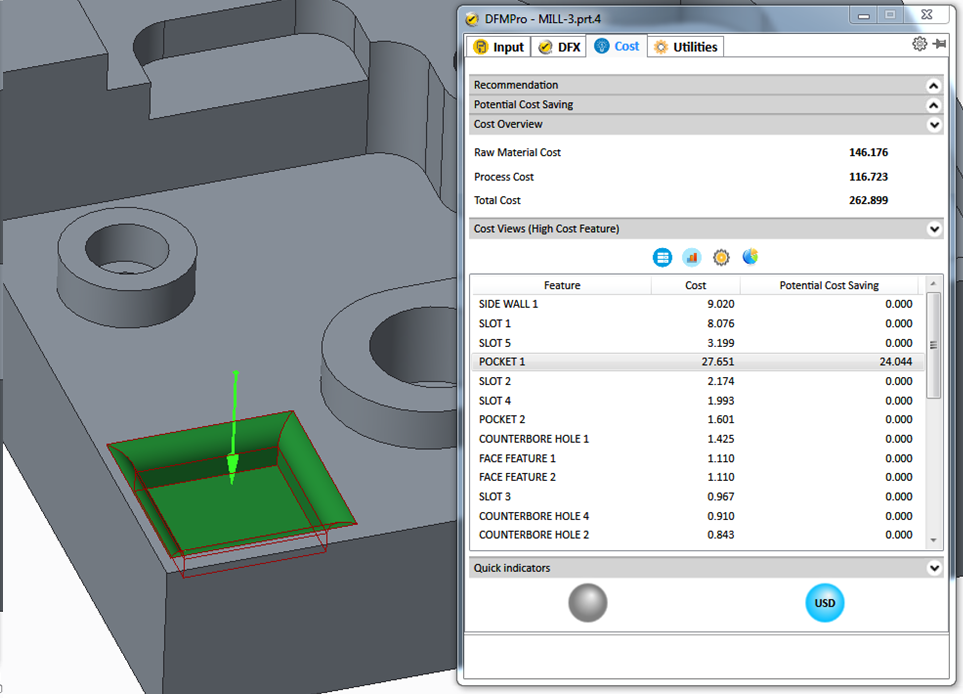

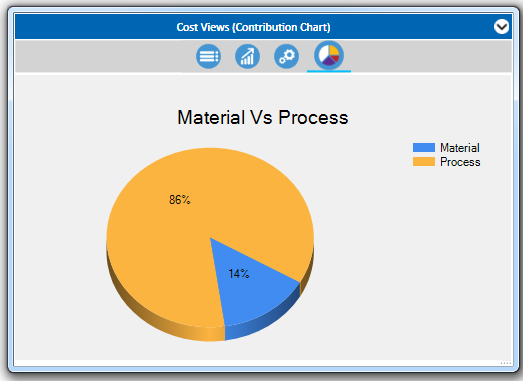

Fig: Cost View

DFX and Cost Views

DFX View: DFX provides a rule-based feedback. Organizational best practices that impact quality are configured in terms of smart checks which, at a click of a button, provide quick feedback on areas of design that violate the best practices. It not only identifies problems, but also suggests solutions to resolve the issues that will impact overall product cost. These impacts are mostly indirect through adverse impact on quality or addition of unnecessary complexity in manufacturing.

Some examples:

Case 1 below depicts a thin steel condition. The combination of the thin steel combined with sharp corners will result in a very weak condition requiring work arounds and/or frequent repair. This not only impacts the overall investment in tooling, but also adds unnecessary down time in in the production process resulting in additional costs.

Case 2 below shows wall thickness as the parameter. The wall thickness here directly impacts the cooling time for part. As stated before, the thickness increases the cooling time proportionately to the square of the thickness. Thus, if the cooling portion of the cycle time is 4 seconds for a 2 mm thick area, it will 16 seconds for a 4 mm thickness in the same part!

Case 1: Increase in tooling cost due to ‘Thin steel’ in tooling of plastics part

Case 2: Thick section in plastic will increase cycle time

Hence the first step for the design engineer before looking in determination of the cost, is to look at the DFM parameters of the design as they may impact the cost that would be difficult to correct later.

Cost is the outcome of what gets decided at design stage. Early decisions are required by the design engineer to not just keep the cost below target but also to optimize the design to balance between the functional requirements and the product cost. This results in value being delivered to the customer. While the functional requirements are a ‘must’ in design, it is also imperative to fully evaluate the various alternatives to achieve them.

Cost Breakdown:

For any manufactured product, the cost is divided into two broad areas, material and processing costs. Additionally, tool costs may also be amortized into the piece price.

Let us take the example of a Zinc (Zamak 3) motor bracket diecasting weighing about 25 gm being molded in a four-cavity tool. The total life of the tool is 1,000,000 shots. It is built out of H13 steel at the cost of $50,000.

The share of each part for this tool is 50,000/1,000,000/4 = 1.25 cent. Hence unless volume is very low, the tooling cost is not considered as part of total cost.

DFMPro cost addon shows this typical breakup of material and process cost to make sure that design engineer is aware about with addition of every feature how cost moves.

Following example depicts a typical chart in DFMPro for such Cost breakup for machined component.

Trade-offs:

At very early stages of design, there are various options or alternatives available that need to be evaluated. Many of the inputs required to make these decisions may not be available in the beginning. However, based on some initial assumptions the Cost Add-on module can facilitate quick evaluation of the options and help select the most suitable one for analysis. In addition to these options, even the design features impact cost. As a result, as features are updated, their respective impacts on cost are immediately shown. Tradeoffs may be required to maintain the cost, as the design progresses from initial design to detailed design. With the built-in cost indicator, upward or downward cost trends can be automatically monitored.

Some of the options design engineers can use for trade-off purpose are:

- Material type and grade

- Manufacturing process chosen

- Region of manufacturing (US, China, Europe, etc.)

- Special features

Apart from the above there are process specific options – for example type of runners (hot or cold) for injection molding, or sheet metal cutting processes such as stamping dies, waterjet, plasma or laser.

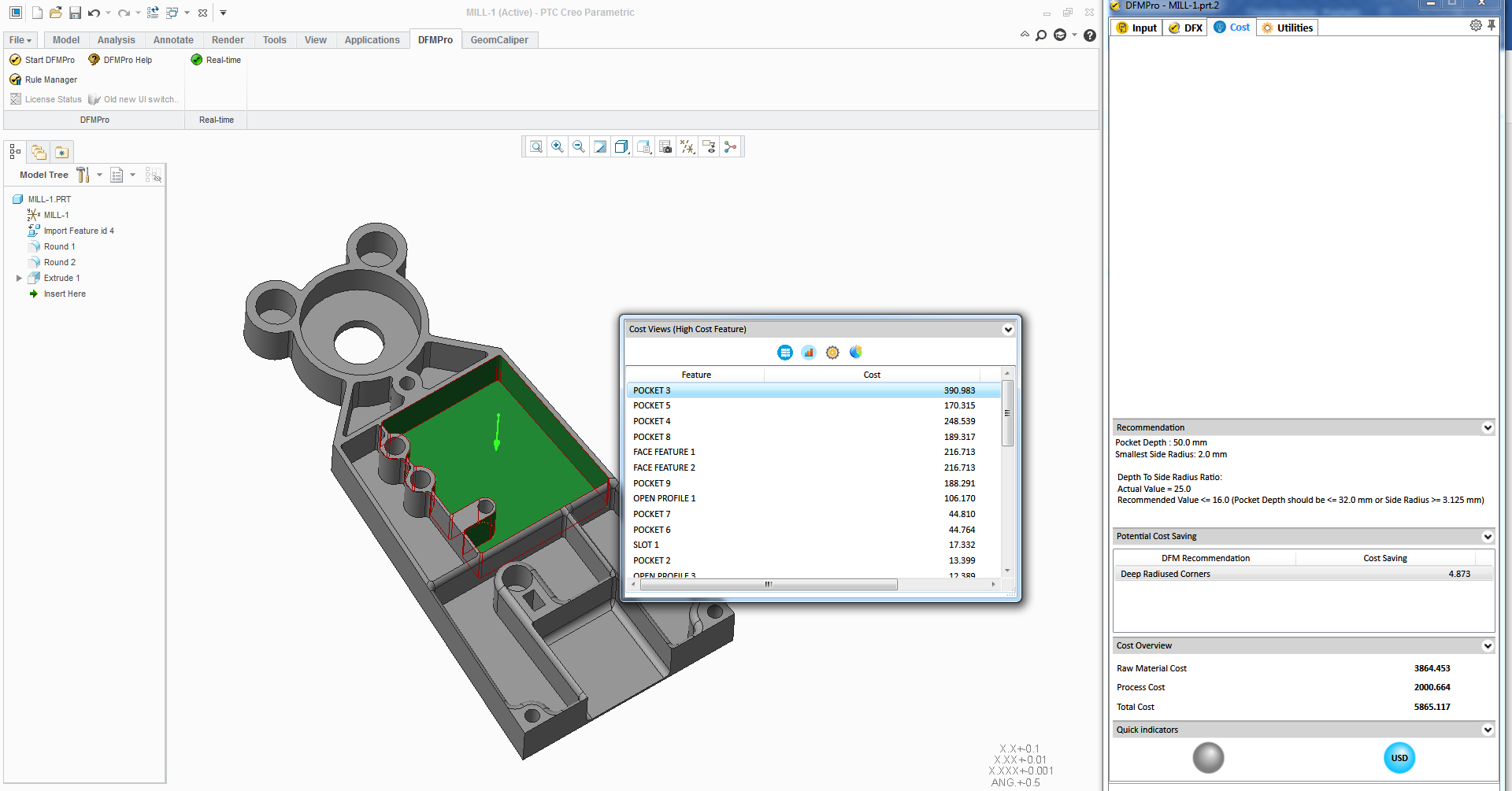

High Cost Features:

There are many variables in the design that impact manufacturing costs for features created on parts such as holes, slots, bends, sharp corners, fillets, etc. The impact of these is almost impossible to review manually during the design stages. This is where DFMPro shines by automatically sorting the costs allowing the designers to focus on the most robust design at the minimum cost.

Feature-wise Breakdown of Costs

DFMPro is meant for design engineers to quickly evaluate design from the quality and cost point of view. The initial cost estimated at the time of design serves as a directional guide and there are no surprises after the design is released for manufacturing. While not necessarily meant for negotiation purposes, its objective is to optimize the design along with the cost. It also reduces the time to design by providing understanding on what parameters drive the cost and quality.

In a nutshell, DFMPro helps in reducing rework and provides great visibility and control over costs while ensuring organizations meet their timeline for delivering great products.

References:

[1] Associated Press – April 1, 2014

[2] CNN Money

[3]http://www.reuters.com/article/2013/04/20/us-boeing-dreamliner-battery-idUSBRE93I11C20130420#oZ88YqvcqMifVimJ.97

[4]http://www.google.com/imgres?imgurl=http://media.philly.com/images/112114_mark-sanchez_600.jpg&imgrefurl=http://www.philly.com/philly/sports/eagles/20141123_Eagles_season_may_hinge_on_which_Sanchez_shows_up.html&h=450&w=600&tbnid=wMIdbnOrpXAKdM:&docid=khettPElJgPphM&ei=T8BMVtiBIcLs-QGkpYKIDg&tbm=isch&ved=0CEcQMyggMCBqFQoTCJjltovKmskCFUJ2PgodpJIA4Q

[5] D. Wright; Failure of Plastics and Rubber Products, Smithers Rapra (2001) p. 6

[6] Robust Plastic Product Design: A Holistic Approach

https://www.hanser-fachbuch.de/autor/Vikram+Bhargava