This is my second blog post in a series of six about “Holistic Approach to Robust Plastic Product Design”. You can read part I of the series here. Today I will talk about different types of plastic part defects and the common causes of defects. There are 2 types of defects – near term and long term.

Near Term Defects

Near term defects are those that can be easily detected from conventional measurement instruments, visual inspection or mating with parts assembly parts. These defects are typically of 3 types:

- Direct dimensional defects that occur if part features don’t meet the specified tolerance limits

- Indirect dimensional defects if warpage causes dimensions to be out of spec, incorrect fitting with mating parts or inadequate insertion of threaded inserts causing assembly issues

- And visual defects such as gate blush, flow marks, scuffing, short shots and voids, burn marks, non-uniform gloss, non-uniform texture (glossy areas next to dull areas), scuffed texture, sink marks, picture framing, read through and visible knit lines etc.

Long Term Defects:

Most of the long term failures are due to continuous tensile stress in various situations such as

- Plastic parts being force fitted on another parts

- Keeping a boss in a stressed position and not keeping the boss butted up to the mating surface

- If a snap is not allowed to retain its natural position once it is snapped into a particular position

- Selecting a part that is warped during the molding process and straightening it in assembly by fastening screws from the mating part. This is one of the most common and potentially expensive mistake. Believe it or not, sink marks!

Causes of Stress in Plastics

There are several causes for stress in plastics.

Photo Credit: understandingshyness.com

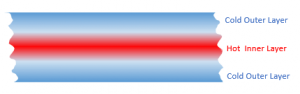

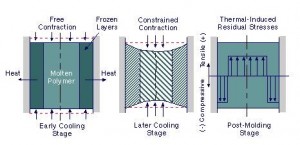

First, plastic is a poor conductor of heat. An injection molded part comes out of a mold at about 200 degree celsius and above. As soon as it comes out, the outer layer gets exposed to ambient air and starts cooling and shrinking. Since the inner layer is insulated by outer layer, it still remains hot and takes much longer to cool down.

First, plastic is a poor conductor of heat. An injection molded part comes out of a mold at about 200 degree celsius and above. As soon as it comes out, the outer layer gets exposed to ambient air and starts cooling and shrinking. Since the inner layer is insulated by outer layer, it still remains hot and takes much longer to cool down.

As a result, the outside layer is continuously pulled inwards by the inner layer and vice versa until the part finally cools down. This results in a following stress pattern.

Illustration Credit: www.dc.engr.scu.edu

Since almost always the applied stress is in tension, outer layer is in a state of compressive stress making the plastic part vulnerable to much higher stress conditions than it would normally undergo in a “neutral” state.

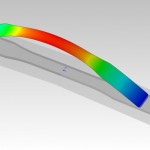

Lets look at another situation when the part is made to bend (or “unbend” in the case of a warped part). Notice, in the following pictures the compressive layer immediately turns into a tensile one, thus making it much weaker. In a state of continuous stress, the load carrying capacity of a plastic part can considerably reduce, making it more vulnerable to chemical attacks and environmental stress cracking (ESC). The part can even fail in conditions of humid air.

Photo Credit: Joseph McFadden – www.mcfaddencae.com

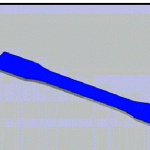

In the following picture, the plastic manifold is warped at about 1.5 mm from both ends. Imagine what can happen to the long term properties of this plastic part if it is tightened into a position where it is “unwarped” in the process. It also effects the load carrying capacity and the chemical resistance of this section.

Photo Credit: www.bmpdesign.com/ Photo Courtesy: http://www.reblingplastics.com

Before I conclude this part of the blog, I would like to explain why sink marks occur.In a plastic part, if there is a heavier cross section surrounded by smaller ones, then the smaller sections can cool and contract much faster than the former. As a result, heavier sections continue to cool and shrink, pulling in layers from above, causing severe tensile stress to the compressive layer in this section.

So whats the solution to this problem. Many factors affect plastic part design. Designers must carefully consider all aspects of plastic properties and systematically follow the design guidelines both empirical and data based that are apply during plastic part design.

In my next blog post, I will explain how a design engineer can substantially reduce most these design problems through an automated design assistant solution, DFMPro.